|

| December 28, 2021 | Volume 17 Issue 48 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New nylon constant torque hinge

Southco has expanded its line of E6 Constant Torque Hinges with a compact, nylon version designed for small applications. The newest addition to the company's E6 50 Constant Torque Position Control Hinge series measures 45 mm with a torque range of 4 to 16 in./lb and is 65% lighter compared to the standard E6 50 Hinge. It provides constant resistance throughout the entire range of motion, enabling users to easily position doors, display screens, and other mounted components and hold them securely at any desired angle.

Southco has expanded its line of E6 Constant Torque Hinges with a compact, nylon version designed for small applications. The newest addition to the company's E6 50 Constant Torque Position Control Hinge series measures 45 mm with a torque range of 4 to 16 in./lb and is 65% lighter compared to the standard E6 50 Hinge. It provides constant resistance throughout the entire range of motion, enabling users to easily position doors, display screens, and other mounted components and hold them securely at any desired angle.

Learn more.

What injection molding material do I use?

How do you decide what type of plastic to use for your next injection molding project? Xometry can help you narrow your choices. Discover the different strengths and applications for materials that could be ideal for your application by learning about the most common plastic injection molding materials in detail.

How do you decide what type of plastic to use for your next injection molding project? Xometry can help you narrow your choices. Discover the different strengths and applications for materials that could be ideal for your application by learning about the most common plastic injection molding materials in detail.

Read this detailed Xometry article.

What are carbon composite bellows springs?

The Carbon Composite Bellows Spring (CCBS) from MW Components is a system of carbon fiber elements that combine to work as a high-performance, lightweight, and design-flexible compression spring meant to replace coil springs or metallic Belleville disc springs. A functional spring is made from several individual elements paired and joined to make a stack. The stack spring rate is determined by the number of elements, the base rate of each element, and their series or parallel orientation in the stack. Applications include motorsports, aerospace, and high-performance activities.

The Carbon Composite Bellows Spring (CCBS) from MW Components is a system of carbon fiber elements that combine to work as a high-performance, lightweight, and design-flexible compression spring meant to replace coil springs or metallic Belleville disc springs. A functional spring is made from several individual elements paired and joined to make a stack. The stack spring rate is determined by the number of elements, the base rate of each element, and their series or parallel orientation in the stack. Applications include motorsports, aerospace, and high-performance activities.

Learn more.

Conductive Brush Ring overcomes current leakage in EV powertrains

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

Learn more.

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

One-part epoxy changes from red to clear under UV

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Learn more.

SPIROL Press-N-Lok™ Pin for plastic housings

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

Learn more about the new Press-N-Lok™ Pin.

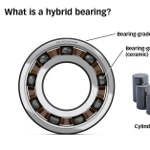

Why hybrid bearings are becoming the new industry standard

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

Read the SKF technical article.

3M and Ansys train engineers on simulating adhesives

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Read this informative Ansys blog.

New FATH T-slotted rail components in black from AutomationDirect

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Learn more.

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

Learn more.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

New interactive digital catalog from EXAIR

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

Check out EXAIR's online catalog.

5 cost-saving design tips for CNC machining

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

View the video.

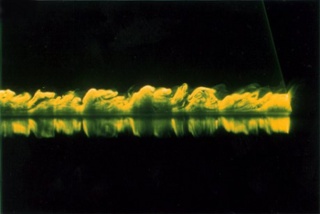

Mathematicians derive the formulas for boundary layer turbulence -- 100 years after phenomenon was first described

Turbulence makes many people uneasy or downright queasy, and it's given researchers a headache too. Mathematicians have been trying for a century or more to understand the turbulence that arises when a flow interacts with a boundary, but a formulation has proven elusive.

Now, an international team of mathematicians, led by University of California (UC) Santa Barbara professor Björn Birnir and the University of Oslo professor Luiza Angheluta, has published a complete description of boundary layer turbulence. The paper appears in Physical Review Research and synthesizes decades of work on the topic. The theory unites empirical observations with the Navier-Stokes equation -- the mathematical foundation of fluid dynamics -- into a mathematical formula.

Large eddies in a turbulent boundary layer. [Credit: M. GAD-EL-HAK]

This phenomenon was first described around 1920 by Hungarian physicist Theodore von Kármán and German physicist Ludwig Prandtl, two luminaries in fluid dynamics. "They were homing in on what's called boundary layer turbulence," said Birnir, director of the Center for Complex and Nonlinear Science. This is turbulence caused when a flow interacts with a boundary, such as the fluid's surface, a pipe wall, the surface of the Earth, and so forth.

Prandtl figured out experimentally that he could divide the boundary layer into four distinct regions based on proximity to the boundary. The viscous layer forms right next to the boundary, where turbulence is damped by the thickness of the flow. Next comes a transitional buffer region, followed by the inertial region, where turbulence is most fully developed. Finally, there is the wake, where the boundary layer flow is least affected by the boundary, according to a formula by von Kármán.

The fluid flows quicker farther from the boundary, but its velocity changes in a very specific manner. Its average velocity increases in the viscous and buffer layers and then transitions to a logarithmic function in the inertial layer. This "log law," found by Prandtl and von Kármán, has perplexed researchers, who worked to understand where it came from and how to describe it.

The flow's variation -- or deviation from the mean velocity -- also displayed peculiar behavior across the boundary layer. Researchers sought to understand these two variables and derive formulas that could describe them.

In the 1970s, Australian mechanical engineer Albert Alan Townsend suggested that the shape of the mean velocity curve was influenced by eddies attached to the boundary. If true, it could explain the odd shape the curve takes through the different layers, as well as the physics behind the log law, Birnir said.

Fast forward to 2010, and mathematicians at the University of Illinois released a formal description of these attached eddies, including formulas. The study also described how these eddies could transfer energy away from the boundary toward the rest of the fluid. "There's a whole hierarchy of eddies," Birnir said. The smaller eddies give energy to the larger ones that reach all the way into the inertial layer, which helps explain the log law.

However, there are also detached eddies, which can travel within the fluid, and these also play an important role in boundary layer turbulence. Birnir and his co-authors focused on deriving a formal description of these. "What we showed in this paper is that you need to include these detached eddies in the theory as well in order to get the exact shape of the mean velocity curve," he said.

Their team combined all these insights to derive the mathematical formulation of the mean velocity and variation that Prandtl and von Kármán first wrote about some 100 years earlier. They then compared their formulas to computer simulations and experimental data, validating their results.

"Finally, there was a complete analytical model that explained the system," Birnir said. With this new mathematical formulation, scientists and engineers can adjust different parameters to predict the behavior of a fluid.

Boundary layer turbulence appears in all sorts of fields, from transportation to meteorology and beyond. "I think it's going to have a lot of applications," Birnir remarked. For instance, a proper understanding of boundary turbulence can help make more efficient engines, reduce pollutants, and minimize drag on all sorts of vehicles.

Earth's atmosphere can be modeled as a boundary flow. Despite its apparent height, the atmosphere is essentially a thin shell of moving air hugging the planet's surface. "I think, ultimately, we will be able to use this theory to understand both atmospheric turbulence and the jet stream," Birnir said. "It's going to be quite useful."

The authors were surprised to discover how important detached eddies were, especially in explaining the turbulence transition in the buffer layer. Studying their behavior has begun to provide insight into other types of turbulence.

"In particular, we get insights into Lagrangian turbulence," said Birnir. This theory describes turbulent behavior in a reference frame that moves with the flow, like a raft on a river. This contrasts with Eulerian turbulence theory, which describes the fluid as it moves past a fixed reference frame, like a pier on the riverbank. Attached eddies disappear in the moving reference frame -- much like a current seems to disappear when you're headed downstream. "But the detached eddies are still there," Birnir said, "and they seem to play a major role in Lagrangian turbulence."

The team is currently focused on exploring Lagrangian turbulence with these new tools, which themselves originally came from work on homogenous turbulence, where there is no boundary. "Insights that you get in one field help you in another," Birnir said.

Source: University of California - Santa Barbara

Published December 2021

Rate this article

View our terms of use and privacy policy